Grit Technology

Knowing which abrasive mineral to use when sanding is important not only to avoid damaging surfaces, but also to make the sanding operation more efficient and less time-consuming; which is to be welcomed, as sanding is usually a monotonous, time-consuming task that causes discomfort to the operator's hands.

Not all materials have the same hardness, and therefore they behave differently when mechanically treated. Although this is obvious, it is often overlooked and resources and time are wasted, ultimately increasing the cost of sanding.

The minerals used today are all of synthetic origin, since they offer greater advantages and greater uniformity in all their properties, which is decisive in industrial applications.

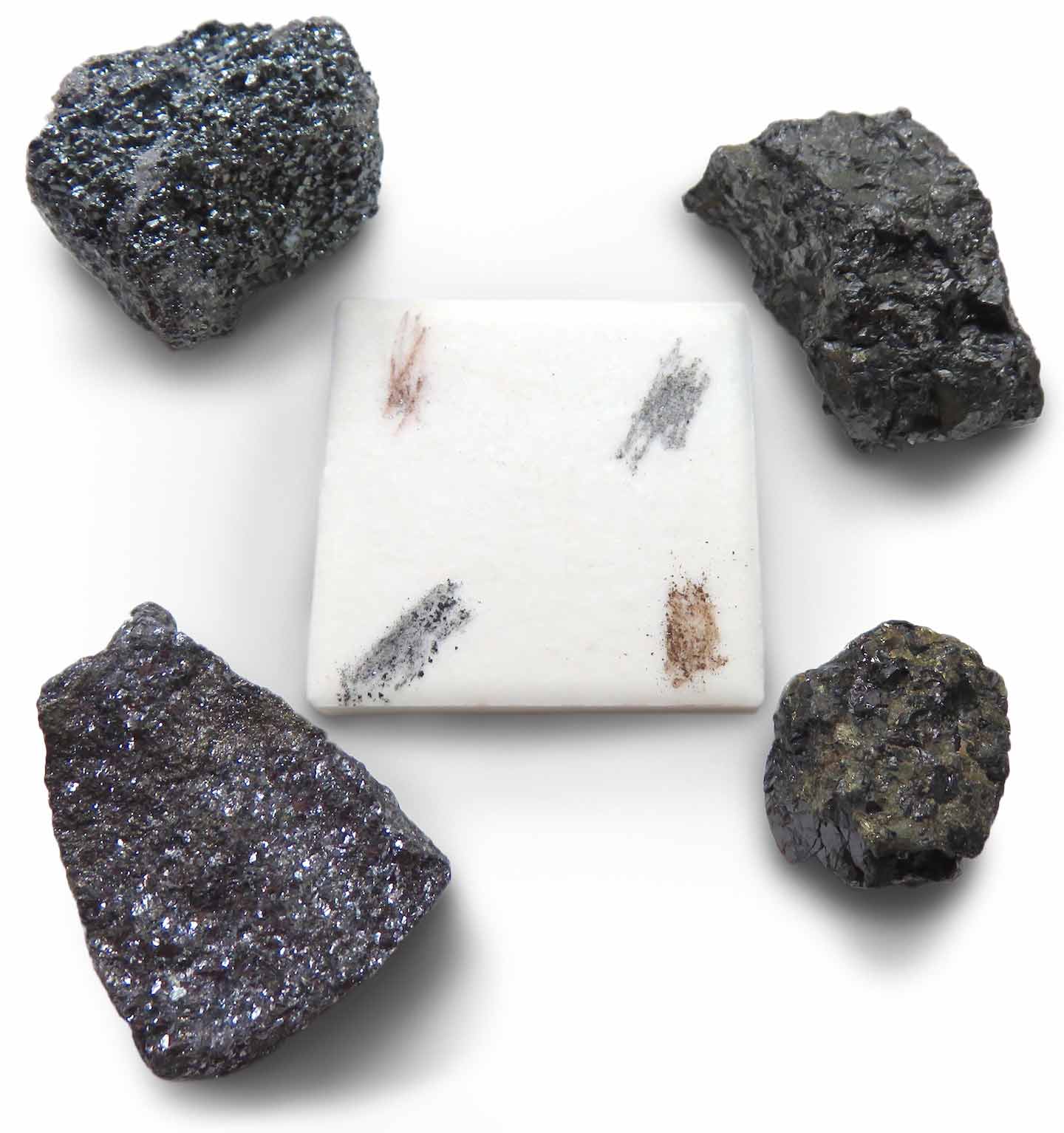

Shape and structure of minerals

Knowing their shape and structure is key to good sanding, since the lower the friction, the lower the heat generated and therefore the more effective the cutting of the mineral will be, the material will not burn and it will clog less.

Therefore, the effectiveness of the cut will depend very much on the shape and structure of the minerals. To achieve clean cuts, which generate less heat, it is necessary to use very sharp minerals. On the other hand, rougher cuts generate higher friction and temperature, making it necessary to use minerals with conglomerate structures.

Mechanical properties of minerals

In addition to shape and structure, each mineral has distinct mechanical properties that enable it to resist scratching, resist impact and self-sharpen. We are talking about the hardness, toughness and friability of minerals. These three properties are key to understanding the behaviour of minerals in surface treatment:

-

To sand a surface (scratch it) we will use a mineral that has a higher hardness than the material of that surface.

-

In order to have starting power (cutting power) we will use minerals that are capable of absorbing the energy generated during these efforts, resisting breakage.

- To maintain the cutting power over time (self-sharpening), we will consider those minerals that can fracture during operations creating new sharper edges.

Types of Minerals

CR

Ceramic

VERY RESISTANT

- It is a very tough and durable mineral.

- Its structure is microcrystalline and its edges are sharp.

- It is suitable for work on metal and in particular stainless steel.

- The best performances are obtained in operations with high pressures where the mineral fractures, generating new edges.

AG

Compact

LONG-LASTING

- It is a hard and tough, high performance mineral with a consistent finish.

- Its structure is granular, formed by a conglomerate of grits of the same size that form a larger grit.

- It breaks at medium pressure uncovering new grits and generating new edges.

- It is suitable for cylindrical grinding of pipes, grinding of sheet metal and coils.

ZR

Zirconium

STARTING CAPACITY

- It is a hard mineral, with high resistance to breakage and high starting capacity.

- It has a regular crystalline structure and its edges are blunt.

- It breaks at medium pressure generating new edges.

- It has an excellent price-performance ratio.

SC

Silicon Carbide

THE SHARPEST

- It is the most used mineral to achieve the best finishes.

- Its structure is crystalline and its edges are very sharp.

- It wears faster than aluminium oxide, but being very friable it is a durable mineral.

- It breaks easily generating new edges at low and medium pressure.

- It works well on hard materials, rough surfaces and surface polishing operations.

AO

Aluminium Oxide

THE MOST VERSATILE

- It is the most versatile mineral for all materials as it has an ideal combination of hardness and strength.

- Its crystalline structure is irregular and its edges are blunt.

- When it breaks, it does not generate new edges.

- There are three types: Pink and white aluminium oxide work well on soft materials; while brown is suitable for harder materials due to its semi-friable property.

PIRAMIDAL

Pyramidal

EXCELLENT FINISH

- It consists of minerals mixed with resin in the shape of a pyramid, all the same, uniformly micro-replicated.

- Its wear is uniform and continuous.

- It generates excellent finishes and homogeneous surfaces.