¿Necesitas un lijado de precisión sin dañar superficies delicadas? Descubre las ventajas del disco de espuma estándar...

}Plane sanders, also called contact sanders or belt sanders, are sanding machines for industrial use. They are used for sanding flat surfaces for their subsequent treatment and finishing.

These large belt sanders are generally used in the wood and part varnishing industry. Also in other sectors such as:

Metal, for sanding and satin finishing of steel and aluminum plates.

Footwear, for calibrating and sanding rubber and EVA sheets.

Tanning, for the treatment and polishing of the hides.

There is a wide range of specialist manufacturers in the market in each sector; specific machine models for each sanding surface and application.

Despite this diversity of options, most belt sanders have the same principles of operation and adjustment (as far as sanding variables and pressure are concerned).

Accessories for belt sanders essential in all types of jobs

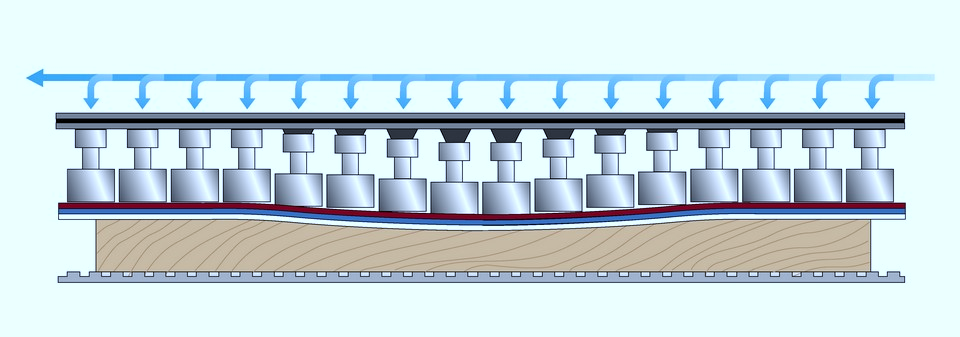

The sanding belt, or abrasive belt, is not the only consumable used during the performance of the work with the belt sander. Particularly in surface finishing or superfinishing work, plane sanders incorporate sanding units called "skid group".

Unlike contact roller group sanding units, sanding pressure is transmitted from the sander to the workpiece via a pressure beam or bar.

The technology used in this pressure bar has evolved a lot in recent years, becoming a key element for the precision sanding of pieces with high added value.

But this technology can be diminished if we do not take into account the accessories subject to wear that the skate group incorporates, and whose condition we must check with certain frequency:

graphite sheet

felt sheet

These two elements are very important when it comes to achieving the best finish on the treated surface. Any damage or deterioration in them will cause defects in the sanded and subsequently finished surfaces.

The importance of the graphite sheet, do you know what it is for?

It is a fabric covered on one of its faces with graphite particles arranged in the form of granules or in the form of flakes. On the graphite side, it is dark gray and stains easily when handled, on the back you can see the white fabric.

The main function of the graphite sheet is to reduce the temperature generated by the friction between the pressure beam/felt and the abrasive belt during sanding operations.

It acts as a “dry lubricant”, preventing abrasive belts from quickly clogging up during sanding due to the heat generated.

There are different types on the market depending on the sanding operation and the type of material to be treated. The main types are:

Extra resistant graphite for high performance in sanding boards and panels.

Graphite for heavy gauge and roughing operations.

Graphite for finishing sanding and polishing of parts.

Graphite for wet sanding for the metal industry.

Graphite for applications requiring high flexibility.

The main characteristics that we must assess for choosing one or another type are:

The degree of flexibility

The temperature resistance

The durability

And the versatility

The strongest graphites combine synthetic graphite particles with natural graphite particles arranged in successive layers for progressive wear.

In the case of wide belt sanders, the graphite sheet is subjected to constant friction during operation, and therefore to progressive wear. Its physical appearance must be checked frequently, avoiding any bowing or bending of its surface since it is a delicate and brittle material, which must be handled with care.

The main defects that usually appear on the graphite itself are scratches or pressure marks generated by the sharp edges of the sanded parts. We must replace it when its surface is damaged or has lost uniformity, as the graphite layers wear out and the threads of the support fabric are exposed.

Generally, the precautions and cares with the graphite sheet are not taken into account; and as a consequence, various defects are caused on the sanded parts that could be avoided with simple maintenance operations.

Felt strip functions

Felt is a material that is made of natural or synthetic wool fibers, pressed and compacted together using resins. The format of use is a strip whose dimensions are established by the manufacturer of the machine; although in general, the widths oscillate between 7-10 cm and the lengths between 100-140 cm.

Its main function is to transmit the pressure generated by the pressure bar to the abrasive belt evenly over the entire contact surface. The graphite sheet is placed between both elements, which reduces friction between them.

There are different thicknesses and densities of felt. The most common thickness is 10 mm and the density is 0.40 Kg/m3. Unlike graphite, felt is less exposed to rapid wear, but it must also be checked as any loss of thickness, marks or deterioration will result in marks or defects during sanding.

At Abracom, we are specialists in treating belt sander sanded surfaces. We have all the options for technical advice and supply of graphite strips and/or rolls, with and without self-adhesive, and felt strips for the skids of contact sanders and other auxiliary machines.

(1).png)

(1).png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)